Principes techniques

1. Nouvelle découverte: Une nouvelle façon de se souvenir de la faible planification magnétique des champs magnétiques

Au milieu des années 1980, les scientifiques de l'entreprise ont commencé à étudier le phénomène des "champs magnétiques à mémoire". En explorant l'état de changement des "domaines magnétiques" et des "moments de spin électronique" des substances microscopiques formées par l'effet quantique de nombreux corps dans les matériaux ferromagnétiques, ils ont découvert qu'à l'état naturel, les "vecteurs" des domaines magnétiques et des moments de spin électronique des arrangements microscopiques à l'intérieur des matériaux ferromagnétiques sont dans un état désordonné ; dans les conditions d'une intervention humaine, il y a un changement dans le modèle de mouvement ; dans le cas d'une intervention humaine, il y a un changement dans le modèle de mouvement. "L'application d'un champ magnétique de mouvement au matériau ferromagnétique peut modifier le nombre de domaines magnétiques et le vecteur du moment magnétique de spin électronique, de manière à obtenir un produit d'énergie magnétique de faible magnitude modérée, formant ainsi un "champ magnétique de mémoire". ".

Cette découverte est d'une grande importance, car elle a non seulement créé de nouveaux principes microphysiques de "synthèse du vecteur du champ magnétique spatial", mais elle a également jeté les bases théoriques d'une nouvelle branche du magnétisme, la "science du champ magnétique de la mémoire". Sur la base de cette découverte, les scientifiques de l'entreprise ont inventé une nouvelle "technologie d'essai non destructif de la mémoire magnétique faible", qui permet de distinguer les caractéristiques physiques des matériaux dans l'état de la technologie de détection de la mémoire magnétique faible, de renverser la technologie traditionnelle de détection de la mémoire magnétique forte, et d'atteindre un niveau de pointe international dans le domaine de l'essai non destructif des matériaux ferromagnétiques.

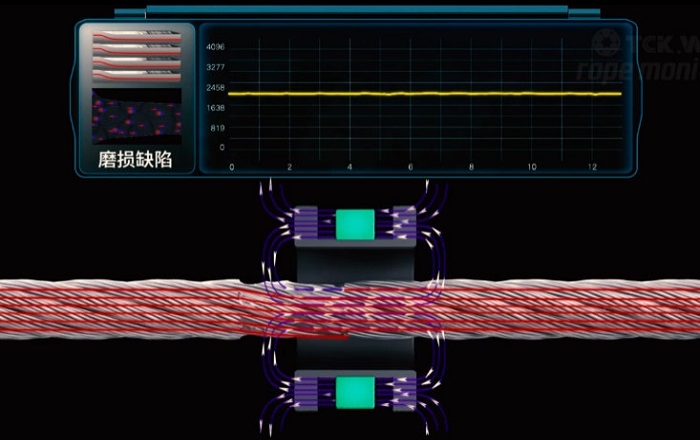

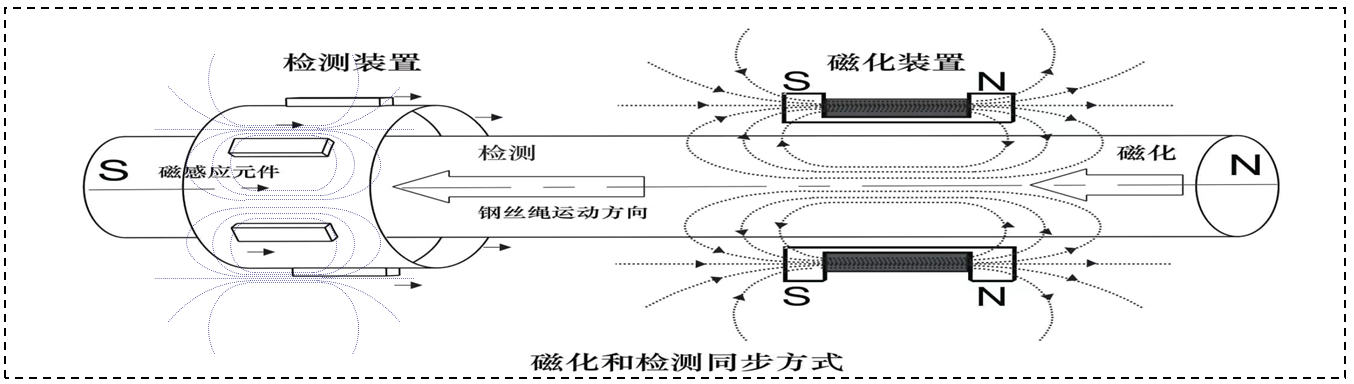

Principe de la technologie de détection magnétique faible pour les câbles métalliques

Système expert de surveillance intelligente des câbles métalliques

2. Nouvelle invention : Nouvelle technologie pour la perception magnétique faible du champ magnétique de mémoire

Le produit d'énergie magnétique établi le long de la direction axiale du câble est distribué de manière égale, uniforme et continue ; le produit d'énergie magnétique à l'intérieur de tout élément de volume devrait donc également être distribué de manière égale, uniforme et continue.

La densité des lignes de force magnétiques est la même, les flux sont égaux, et un champ magnétique mémorisé donné est ainsi formé.

Le champ magnétique de la mémoire ne disparaît pas avec la suppression du champ magnétique externe, mais reste stable pendant une longue période tant que des conditions telles que de fortes vibrations mécaniques ou des températures élevées ne se produisent pas.

Caractéristiques techniques : détection sans contact à large portée ; acquisition continue et ininterrompue d'informations sur les différences de potentiel magnétique ; analyse quantitative des dommages tels que rupture de fils, abrasion, corrosion, fatigue, etc.

3. Nouvelle création : équipement d'inspection intelligente des câbles métalliques

● Nouvelle création : équipement d'inspection intelligente des câbles métalliques

● Les lignes de force magnétiques ne peuvent être disposées que le long de trajectoires irrégulières à faible énergie dans les éléments de volume dégénérés. La densité du flux magnétique varie alors et la distribution du produit énergétique magnétique semble inhomogène, produisant des différences dans la distribution du potentiel énergétique magnétique à travers les éléments de volume

● Plus la métamorphose est importante, plus la différence de potentiel d'énergie magnétique est marquée.

● En calibrant les informations relatives au potentiel d'énergie magnétique de la mémoire des éléments de volume normaux du câble et en les comparant aux informations extraites des éléments de volume défectueux, la différence de potentiel d'énergie magnétique du matériau de charge due à la dégradation peut être efficacement identifiée.

● L'analyse de la relation quantitative entre ces informations physiques variables et les propriétés mécaniques de charge correspondantes permet d'atteindre l'objectif technique de la détection quantitative des câbles d'acier.

4.Six innovations et deux percées

1. Innovation théorique : création du nouveau principe de "synthèse du vecteur champ magnétique spatial".

2. Innovation méthodologique : découverte d'une nouvelle méthode de "planification de la mémoire magnétique" (brevet d'invention)

3. Innovation méthodologique : découverte d'une nouvelle méthode de "planification de la mémoire magnétique" (brevet d'invention)

4. Innovation matérielle : invention d'un nouveau matériau pour une fine bande d'alliage magnétique doux amorphe (brevet d'invention)

5. Innovation algorithmique : méthode d'évaluation non destructive de la performance de charge des câbles métalliques (brevet d'invention)

6. Innovation produit : invention d'une série de produits de détection magnétique de la faiblesse des câbles métalliques (brevet d'invention)

Percée 1 : passage de la détection qualitative à la détection quantitative ;

Deuxième avancée : l'inspection par intelligence artificielle remplace l'inspection manuelle